Survey and Inspection

Rig Move & Positioning

Offshore Construction Support

Geophysical & Geotechnical

Semi-Sub Rig Moves

KG position semi-submersible rigs safely as per project requirements within tolerance location. KG also supports pre-installing anchors using an AHV complete with ROV, prior to the actual rig move.

Jack-Up Rig Moves

KG have well proven standardised solutions based on Global Navigation Satellite System (GNSS) positioning in combination with relative positioning systems. These include automatic total stations which are used to navigate the rig in a safe and controlled operation alongside platform.

FPSO Operation

KG provide survey and positioning support during initial hook-up, reinstatement and mooring inspection or repair. KG also provide survey support for FPSO heading control AHV.

Well Setting

KG determine Subsea position with Long Baseline systems (LBL), heading, inclination and height of a wellhead.

Rig Site Debris Survey

GVI, multibeam and side scan sonar available for debris clearance survey for rig approach final location, anchors and mooring line positions.

Geophysical & Geotechnical

Offshore Construction Support

Geophysical & Geotechnical

Engineering Analysis Subsea Surveys

We support gathering of Geophysical data to support FEED, drilling, construction and asset maintenance studies.

Pipeline and Cable Route Surveys

We perform inspections, collect data, locate buried lines, free span, depth of burial and visual survey to determine that the products are in the correct position and to ensure there are no risk of damage. Also cathodic protection service (CP) which works towards preventing corrosion on our clients’ pipelines.

Decommissioning Seabed Survey

KG provide assistance to you before, during, and after your decommissioning project. This includes initially researching to determine if any pipelines, subsea infrastructure, or hazards exist within your operating areas, performing geophysical surveys to verify appropriate anchor touchdown locations, providing surface navigation for support vessels, and performing post-decommissioning clearance surveys.

Route Clearance Surveys

KG help establish the optimum information on bathymetric, debris and seabed level of pipeline/cable route.

Offshore Construction Support

Offshore Construction Support

Offshore Construction Support

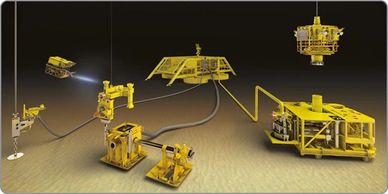

Surface and subsurface Installation Support

KG provide precise positioning of infrastructure for the development, management, and execution of projects from conception to decommissioning. Positioning and orientation of jackets, templates, caissons, PLETS, PLEMS, jumpers, umbilicals and any other marine related assets.

Pipe & Cable Laying

KG supports pipeline laying process from developing an appropriate route, positioning surface vessels, monitoring the pipeline’s touchdown monitoring, executing post-lay surveys and reporting. USBL and LBL positioning can be provided for as-built surveys, depth-of-burial surveys, mat placement and any pipeline activity.

Trenching Support

KG provide detailed surveys of pre-trench and post trench corridors to design cost-efficient, practical, safe routes and depth of burial for various project requirements and installations.

Inspection Repair & Maintenance Support (IRM)

IRM is part of daily routine for existing fields, and KG is well placed to support such operations for vessel’s own contractors.

Subsea Metrology

Subsea Metrology

Offshore Construction Support

KG specialise in inertial, acoustic and 3D laser metrology techniques which are employed to accurately measure distances, elevations and orientations of connecting subsea assets.

Comprehensive positioning services are provided for the subsea assembly process.

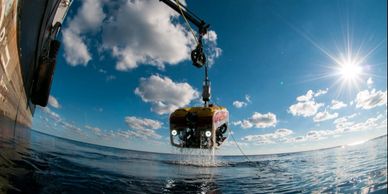

ROV Support

Subsea Metrology

Dive Support

Ultra Short Baseline (USBL) and Long Baseline (LBL) are subsea positioning techniques employed for ROV positioning. A variety of ROV positioning services routinely provided by KG include Inspection Repair and Maintenance (IRM) operations involving choke changes, power pod replacements, flying lead repairs, touchdown monitoring of pipelines and umbilicals, archaeological inspections of shipwrecks, push coring acquisition, pipeline depth-of-burial surveys and detailed inspections of pre-lay pipeline routes.

Dive Support

Subsea Metrology

Dive Support

KG provide acoustic positioning and high-resolution 2D real-time imaging sonar services for diver tracking and support.

KG Survey can support most diving related Inspection Repair and Maintenance (IRM) operations.

Cathodic Protection (CP)

Flooded Member Detection (FMD)

Flooded Member Detection (FMD)

Cathodic protection surveys verify whether or not the anodes protecting an asset are working. By recording CP potential measurements and making visual assessments of the anodes and coating, a knowledgeable CP engineer will determine if corrosion is fully arrested and predict the remaining life of the anode system, also make recommendations to correct corrosion issues. KG use the best latest technology sensor in the market for this service.

Flooded Member Detection (FMD)

Flooded Member Detection (FMD)

Flooded Member Detection (FMD)

KG has been providing a cost effective approach for the rapid surveying of Marine platform jacket members to determine the presence and degree of water ingress. KG use a system can measure the degree of flooding into platform structural members without any need to remove marine growth or specialist coatings. It is operable as a simple attachment to any Remotely Operated Vehicle (ROV) or can be manually used by a suitably trained diver. KG provides acoustic and Gamma Ray solution to suits clients need.

General Visual Inspection (GVI)

Flooded Member Detection (FMD)

General Visual Inspection (GVI)

KG provides General Visual Inspection (GVI) to determine the general condition of a structure or component. A GVI will identify gross damage, debris, and major anomalies in the form of video footage with verbal commentary. In the case of a pipeline GVI, a pipeline skid is used, enabling multiple camera angles to be recorded. For most GVIs the observation class ROV is utilised as it is smaller and able to navigate complex structures or restricted areas easier.